A Rare Fish Returns - Building the Sturgeon Nosed Canoe

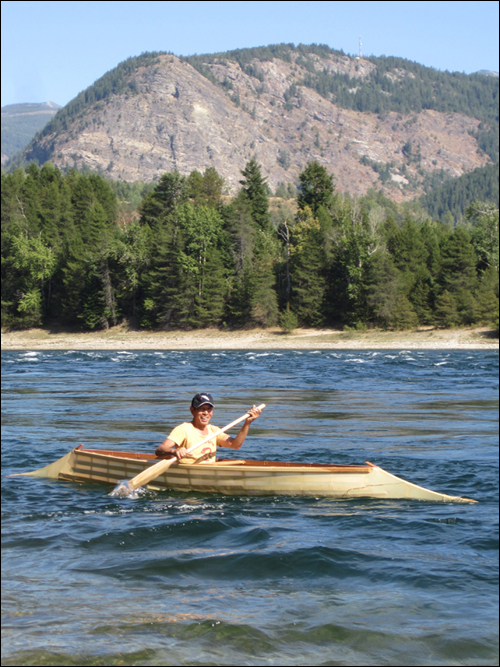

First splash. The sturgeon nosed canoe returns to modern waters.

Click for larger size »

In the summer of 2010 I got a phone call about a canoe that I had built and was selling. The caller was Harry Wong, and he really liked the boat, but what he really wanted was to convince me to build a canoe that his people, the Sinixt Indians had once used. If you haven't heard of the Sinixt (pron. Sin-ite) neither had I nor did I know what a traditional Sinixt canoe looked like. Until he mentioned that it was a sturgeon nosed canoe. And that I knew. Because once seen, it is not forgotten.

Harry gave me a quick family history and how it was that he was tied to this canoe. His mother was Sinixt and father Chinese. Without going into detail here, the Sinixt were pushed off of there land (does this sound familiar?) by the Canadian government, and his grandfather, Alex Christian, is very well known among the Sinixts as the last person to leave their ancestral lands, from what is now known as Brilliant, British Columbia. And when Alex Christian departed, he left in a sturgeon nosed canoe, paddling down the Columbia River.

Sinixt and dog in sturgeon nosed canoe.

Photo: Arrow Lakes Historical Society

http://www.firstnations.eu/invasion/sinixt.htm

I also found out from Harry that there were upcoming festivals commemorating the 200th anniversary of explorer David Thompson's arrival at the confluence of the Kootenai and Columbia Rivers. And Harry thought it would be great to have a sturgeon nosed canoe there as a cultural exhibit.

But as interesting as a build like this might be, I already had a number of boats on my todo list and so I wasn't sure that I could afford to get side tracked off on to someone else's project. I do well enough getting side tracked on my own. So I didn't say yes, but I didn't say no. Always enthusiastic about the prospect of the project, Harry would call me from time to time and touch base and so finally in March of 2011 I decided to pull the trigger and build a sturgeon nosed canoe.

Up until we had only communicated by phone, so we finally met in person for the first time in a coffee shop where Harry gave me a book on the history of the Sinixt (The Geography of Memory by Eileen Delehanty Pearkes). The book contained old photos of sturgeon nosed canoes that I had never seen before and even pictures of Harry's grandfather, Alex Christian. I read the book cover to cover and pulled together everything else I could find about the boat. And along the way, I learned a bit about the people who made and paddled them.

Bringing Choices Together

In building a replica-interpretation one might think that all that a person is doing is making a copy of an old boat, but it always seems to expand into much more than just "building a boat". Because there is no assembly line for these types of builds and very little in the way of plans. Each build seems to move in a direction of its own. There are always so many questions to be explored about building techniques, materials, and design.

The ends on a sturgeon nosed canoe make a boat that seems to be upside down.

Click for larger size »

So perhaps it was the materials used that dictated the design. But for some reason when canvas became available the switch from canvas to bark was made, while retaining the same ram ends. David Thompson wrote in his journals that they were more stable in the wind and the Indians he talked with claimed that the ram ends helped tracking in swift water. Perhaps then the ram ended design suited the local conditions. Or maybe it was just tradition. But in the end the choices that all boat builders have to make are what connects all builders together, around the world and throughout time.

And that is why boat building is about so much more than just building a boat.

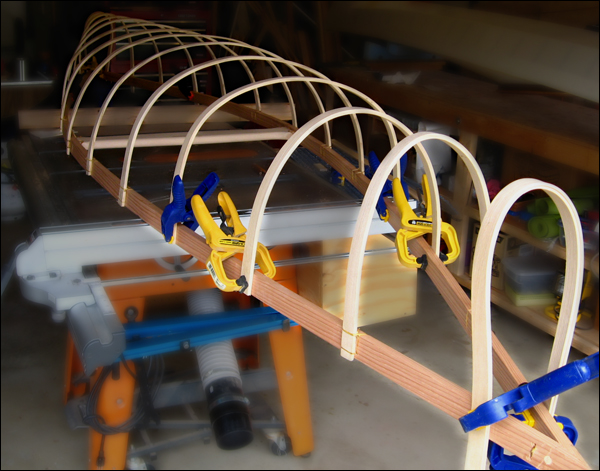

The Build

SOF boats are popular because they are light, flexible, easy to build, and inexpensive. I started building them when I was looking for an alternative to the ubiquitous fiberglass boats. They are also a quick way to recreate and study the ancient SOF craft, build experimental designs, and sometimes are built to copy boats originally built from the "other" materials.

In building a SOF boat, one lashes and wooden pegs together a lattice frame, covers it with fabric, and then fills in the weave with some sort of waterproofing - usually a paint or epoxy. When you are done, even though it may look like a bunch of sticks all tied together, you are rewarded with a quality product that is light, fast, and guaranteed to attract lots of attention at the boat launch.

Building a replica-interpretation as opposed to a strict replica allows me to keep an open mind when dealing with materials, design and tools. The original builders used what was available to them and I do too. The overlap that occurs between the old and the new is a learning opportunity. I decided to build this frame using mostly western red cedar because it is a local wood that the original canoe frames were built from and is light and rot resistant. The thwart and the rub rails were built from pine and ash respectively for strength. The wood for the ribs were made from ash for it's ease in bending. For lashings I use artificial sinew, a waxed nylon line used by leather workers and now popular among SOF builders. It is made of fibrous nylon strands and stretches when pulled, creating an extremely tight lash.

Gunwales and ribs start the build off.

Bark canoes usually start with the skin being propped into place, but SOF construction starts with the frame first. It can be overwhelming, seeing all of the lashing that has to be done. But a rhythm settles in and I'm always surprised when I tie the last knot because I just never see it coming. Standing back to look for anything else that needs to be done, it's such a delight to realize that I'm done! So I take a few minutes to look over everything, admire this part of my handiwork, and rue over the fact that I'm going to have to cover it all up with fabric.

The finished frame, oiled and ready for the "saran-wrap test"

Click for larger size »

After I have admired my handiwork enough I oil the frame with tung oil and move on to the next step, which is guaranteed to raise eyebrows at the beach. The craft is shrink wrapped, floated, and paddled around for 5 or 10 minutes - or until the water gets too deep inside. This time honored procedure is affectionately dubbed the "saran-wrap test" by SOF builders and is done because it is far better to find any mistakes in the frame build now than after it has been skinned and painted.

Shrink wrapped and paddled to test the frame

Click for larger size »

Next the skin goes on. There are a lot of different coverings, but I like to use ballistic nylon, called so because it was once used for bullet proof vests. I'm not keen on testing that fact out, but it is pretty tough. The edges need to be melted to keep it from fraying so I use a soldering iron with the tip filed to an edge to cut with.

The fabric is rough cut and laced in place with mason line across the gunwales. The ends are then sewn up. First they are just basted into place and then trimmed with the hot knife to about 1/2" away from the basting. After that I go over it one more time with a simple whip stitch. There are a wide variety of threads that can be used, but I use dental floss. It's also nylon and it works!

Once the skin is sewn on it is wetted out and ironed. The nylon shrinks up like a drum and in fact, if it is sewn on too tightly it can actually break the frame. It's one mistake I have yet to make, but I have received some pretty nerve wracking cracks and pops on some of my builds.

Melting holes with a soldering iron allows the skin to be laced up like a shoe

Click for larger size »

The next choice to make is what kind of finish to put on the skin. I use oil based polyurethane floor paint or similarly, spar varnish. Nothing sticks to nylon so it is important to get the paint into the weave. I've never had a problem with this and have never found it necessary to thin the paint. My method is to use a small roller to apply and tip it out with a brush. I used to put on 2 or three coats and it worked fine, but on my last several boats I upped that to 6 or 7 coats in order to fill the weave of the fabric. The finish is smoother, more attractive, the skin is noticeably tougher, and the boat glides better on the water.

Once the final coat is on it's time to clamp the skin in place with the rub strips. Although I don't use metal on these boats, here is the one exception. I countersink holes in the rub rail and insert stainless screws. The screws go through the rub rail, into the out-wale, through the rib end, and into the in-wale. I know that some people will also lay down a line of stainless steel staples along the skin and into the out-wale before attaching the rub rail, but I have not done that in my canoes and have had no problems. It probably wouldn't hurt but the clamping action of the rub rail against the out-wale seems to work.

The skin is wetted out and then an iron or heat gun is used to shrink the fabric.

On this day, the rain came out to wet the fabric for me.

Click for larger size »

Once the rub rail is attached I run the hot knife along the fabric where it protrudes. This leaves a burn mark along the top of the rub rail/out-wale but if carefully done, it seems decorative to me. If I used staples as I mentioned before I might consider cutting off the fabric just below the top of the out-wale and then attach the rub rail. Finally the rub rail is bunged and finished with spar varnish.

Bungs will be trimmed and the rub rail spar varnished

The Paddle

Traditional water craft deserves a traditional paddle. They usually evolved together for a reason and are an important part of understanding the whole story about the craft. Of course since my boats are not replicas in the strictest sense of the word there is some leeway in the paddle as well. In the case of this canoe I went with the design in Chappelle's line drawings (Bark Canoes and Skin Boats of North America) but laminated the shaft from two pieces of ash for strength and to control warp. The wings of the paddle were attached with an ash spline.

I won't go into the details of paddle construction here but just to say that I was really under a time constraint as I only had a few more days to finish and deliver the boat to Harry. The paddle really came together nicely and although I wish I would have had slightly better proportions in the blade area, it worked fine and looked great.

Launch Day

On launch day, August 9, 2011 Harry and I met and went to a calm place on the lake and paddled for an hour and a half. We switched off and soloed twice and then we paddled double for a while. Unfortunately this is all the experience that I have in the boat so I can't really critique it well. But it seemed to paddle well and was somewhat faster than I had anticipated. When one person paddles it raises the bow and the stern acts like a fin, making it track well. It seemed a little difficult to turn but perhaps that would have gotten better with experience. When two people paddle the bow sinks down into the water and where we were paddling it picked up some seaweed, as I expected that it might.

Harry's first trial. Maybe he is thinking about his grandfather, or maybe he is just concentrating on not tipping over.

Who can say...

The best part about the launch for me was watching Harry. I doubt that anyone in his family had been in a sturgeon nosed canoe in perhaps a hundred years. The canoe is his pride and joy and he is excited about learning to paddle it. For me, when I got in and pulled away from shore it seemed like I was in a time machine, drifting into the past and trying to learn in a physical way why people built these boats the way that they did.

The builder in his creation for the first time

Click for larger size »

Post Script

Since Harry took delivery of the boat and I posted images on the internet, a lot has happened. I've gotten numerous emails and responses on various paddling and building forums and the net keeps widening as I learn more about the boat and the people who made them.

Harry made it just in time to join the 200th anniversary celebrations for the explorer David Thompson. "Our" canoe has not been seen on those waters in many decades and made it into several newspapers and caught the attention of local historians. Although many people knew about the sturgeon nosed canoe, for many it was their first chance to actually see - or paddle one.

Harry and his time machine, photographed on the Columbia River 200 years after David Thompson first arrived.

Click for larger size »

The Sturgeon Nosed Canoe - more video and build pics »